A flat tire on your electric scooter is more than just an inconvenience; it can completely derail your day. But before you start looking up the nearest repair shop, take a deep breath. You've got this. Fixing a scooter tire is a totally manageable job, as long as you know what you’re doing.

The absolute first thing you need to figure out is what kind of tire you have. This one detail changes everything about how you'll tackle the repair.

Your First Step for a Flat Scooter Tire

Seeing that deflated tire is a real bummer, whether you're navigating the busy streets of New York or cruising through Melbourne. But honestly, most punctures are surprisingly simple to fix with the right tools and a bit of patience.

Think of this as your personal cheat sheet for getting back on the road. The most important step is identifying whether you're working with a tubed (pneumatic) or tubeless tire.

Tubed vs. Tubeless: The Critical Difference

So, how can you tell them apart? It's actually pretty simple.

Take a close look at the valve stem—the little nozzle you use to pump up the tire. If you see a nut threaded down against the wheel rim holding the valve in place, you've got a tubeless tire. If the valve stem is just smooth rubber and has a bit of wiggle to it, you're dealing with a classic tubed tire.

Knowing this is crucial because the repair process is completely different for each.

- Tubed Tires: Just like a bicycle, these have a separate inner tube inside the tire that holds the air. When you get a puncture, you have to take the wheel off, pop the tire off the rim, and then either patch the tube or, more often, just replace it.

- Tubeless Tires: These create an airtight seal directly against the rim of the wheel. For smaller punctures, you can often plug the hole from the outside without even taking the wheel off the scooter. It's a much faster fix.

Pro Tip: If you're still not sure, a quick check of your scooter's manual or the manufacturer's website will tell you for sure. Knowing your tire type before you get a flat saves a ton of frustration when you're stuck on the side of the road.

This is the fork in the road for your repair. A tubeless fix can be a quick 15-minute job, while a tubed tire replacement requires more disassembly and effort. To make it even clearer, let's break down the key differences.

Tubed vs. Tubeless Repair At a Glance

Here’s a quick comparison to see the different tools, methods, and typical challenges you'll face depending on your scooter's tire type.

| Feature | Tubed Tires | Tubeless Tires |

|---|---|---|

| Repair Method | Patch or replace the inner tube | Plug the hole from the outside |

| Common Tools | Tire levers, patch kit, pump | Reamer, plug tool, rubber plugs, pump |

| Primary Challenge | Avoiding "pinch flats" during reinstallation | Ensuring the plug creates a perfect seal |

Basically, with tubed tires, the biggest headache is getting the tire back on without accidentally pinching the new tube. With tubeless, the whole game is making sure that little rubber plug seals the hole completely. Now that you know what you're up against, you can gather the right tools and get to work.

Getting Your Tire Repair Toolkit Together

Before you can even think about fixing a flat, you’ve got to have the right gear. Seriously, I've seen people try to pry a tire off with a kitchen screwdriver, and it never ends well. You'll just end up with a scratched-up rim and a whole lot of frustration. Taking a few minutes to get your toolkit ready beforehand changes everything.

The good news is you don’t need a full-blown workshop in your garage. A handful of key items will see you through just about any puncture you're likely to get on US and Australian roads. Having these ready to go means you're always prepared.

The Absolute Essentials

Think of these as your non-negotiables. Without them, you’re pretty much stuck.

- Tire Levers: These are your best friends for wrestling the tire off the rim. Grab a set of two or three made from tough plastic or metal—just make sure they have rounded edges so you don’t gouge your wheel's paint job.

- Air Pump: A small, portable hand pump or a bigger floor pump with a pressure gauge is a must-have. You’ll need it to find the leak in the first place and, obviously, to pump the tire back up to the right pressure once you're done.

- Repair Kit (Patch or Plug): What you need here depends entirely on your tire type. If you have tubes, a standard bicycle patch kit with rubber cement and patches is all you need. For tubeless tires, you’ll want a plug kit, which comes with a reamer tool, an insertion tool, and some sticky rubber plugs.

The demand for these simple DIY solutions is blowing up. The global tire repair kit market was valued at around $2.5 billion back in 2023 and is on track to hit an estimated $4.2 billion by 2033. This surge is all thanks to riders like us who prefer quick, cheap fixes over a trip to the shop. You can read more about the growing market for these essential kits if you're curious.

Nice-to-Have Tools That Make Life Easier

While that first list covers the bare minimum, a few extra tools can make the whole job go a lot smoother.

A spray bottle filled with soapy water is my secret weapon. It’s the fastest, most reliable way to find a slow leak on a tubeless tire—just spray it down and watch for the tell-tale bubbles.

Here are a few other things I always keep handy:

- Allen Keys or Wrenches: Your scooter's axle nuts won't come off with sheer willpower. You'll need a specific size wrench or Allen key to get the wheel off. Figure out what your model uses and toss it in your kit.

- Valve Core Remover: This tiny, inexpensive tool lets you completely deflate a tire in seconds by removing the valve core. It’s a real lifesaver when you're dealing with a stubborn tubeless bead.

- Gloves: A simple pair of mechanic's gloves will keep all that road grime and grease off your hands.

Spending a little bit on these tools now will save you a ton of time, money, and a massive headache later on. With a well-stocked toolkit, a flat tire becomes a minor pit stop, not a day-ruining disaster.

Taking the Wheel Off (Without a Fight)

Alright, this is where a lot of people get nervous, but I promise it's not as scary as it looks. Getting the wheel off your scooter is totally doable. The trick is to be methodical, take your time, and don't try to force anything—especially if you're working on the rear wheel, which is where the motor lives on most scooters.

First things first, let's deal with the motor cables. You'll see a bundle of wires connecting the wheel's motor to the scooter's frame. Sometimes they have a simple quick-disconnect plug, but other times you might need to unscrew a little cover to get to them. Whatever you do, be gentle. The last thing you want is to bend or break one of the connector pins.

Pro Tip I Learned the Hard Way: Before you touch a single bolt, pull out your phone. Take a quick, clear picture of how the cables are connected, the exact order of the washers and spacers on the axle, and the path the wires take. Seriously, this little step will save you a massive headache when it's time to put everything back together.

Freeing the Wheel From the Frame

Once the motor is safely disconnected, you can turn your attention to the axle nuts. These are the big nuts on each side of the wheel that clamp it into the frame. Grab the right size wrench from your toolkit and get ready to loosen them. They're often cranked on there pretty tight from the factory, so you might need to give it some good, steady muscle.

After you've loosened both nuts, you'll feel the wheel start to get a bit of wiggle room. That's your cue to carefully slide it down and out of the dropouts (the U-shaped slots in the frame). Keep an eye on the brake caliper and rotor as you go—you'll need to guide the brake disc out without bending it. And just like that, the wheel is free.

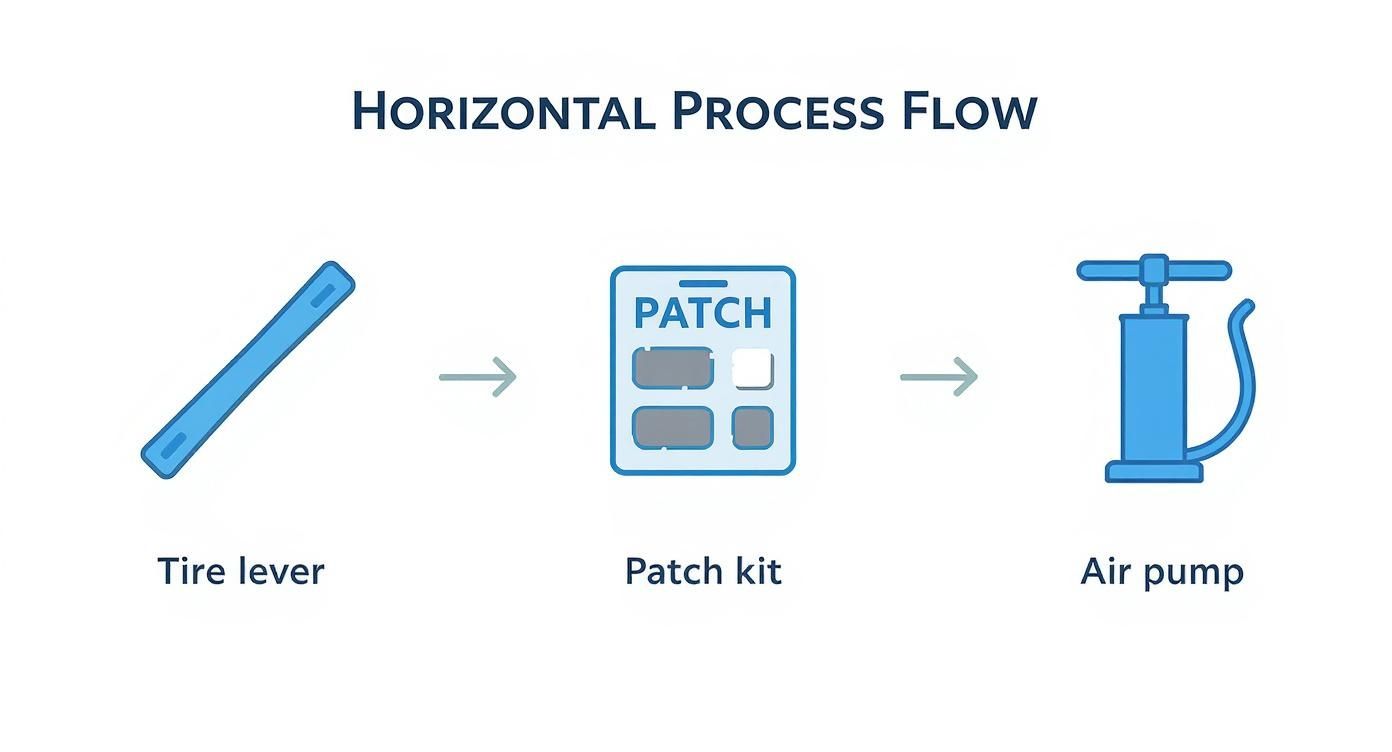

This visual flow shows the core process of any successful repair scooter tire job: using the right tools in the right order.

As you can see, once you've removed the tire with levers, you can move on to the actual repair (patching), and then get it ready for reassembly with the pump.

Prying the Tire Off the Rim

Now for the main event—the wrestling match between you and the tire. The edge of the tire, called the bead, is seated tightly against the rim to create an airtight seal, and it does not want to let go.

Before you start, make sure every last bit of air is out of the tire. If your valve has a removable core, take it out. Then, go around the entire tire, squishing and pushing the bead away from the rim and down into the deep channel in the center of the wheel. This step is crucial because it gives you the slack needed to get your tire levers in.

Once you've done that, you're ready to pry.

- Wedge the first lever in. Shove the spooned end of a tire lever between the tire and the rim.

- Pop the bead over. Pull the handle of the lever down and away, using the rim as a fulcrum to pop a small section of the tire bead up and over the edge.

- Bring in the second lever. A few inches away from the first one, insert your second lever and do the exact same thing. This is usually the point where the tire finally starts to cooperate.

- Slide to victory. With two levers holding a section of the bead off, you can often just slide one of them around the rest of the rim, and the whole side will pop right off.

Flip the wheel over and do it all again for the other side. A buddy of mine swears by using heavy-duty zip ties to squeeze the tire together as he works, which keeps the bead from slipping back into place. It takes some elbow grease, but before you know it, the tire will be completely separated from the rim.

Finding the Puncture and Making a Solid Repair

https://www.youtube.com/embed/nCwWPlaghfs

Alright, with the tire and tube finally off the wheel, it's time to play detective. The culprit could be anything from a tiny, sneaky pinhole left by a shard of glass to a more obvious gash from a nail you ran over last week. Finding it is the most important part of getting this repair scooter tire job done right.

The Old-School Bubble Test

If you're dealing with a classic inner tube, the best method is still the simplest one. Give the tube just enough air to hold its shape, then dunk it in a bucket of water, section by section. Be patient here. You’re looking for a tiny, tell-tale stream of bubbles escaping from the hole. Once you see them, you've found your leak.

For tubeless tires, it's even easier. Just mix some dish soap and water in a spray bottle and give the tire a good spray-down. The air escaping from the puncture will create a foamy, bubbling spot right where you need to work.

Prepping the Area for a Lasting Fix

As soon as you find the hole, mark it! Grab a piece of chalk, a silver marker, whatever you have. Don't think you'll remember where it is, because you won't. Once it's marked, you can let all the air out and get ready to patch things up.

For an inner tube, proper prep is the difference between a permanent fix and a temporary frustration. You're not just slapping a sticker on it; you're creating a vulcanized bond that makes the tube whole again.

- Scuff It Up: Your patch kit should have a little metal grater or a piece of sandpaper. Use it to rough up the rubber around the hole. You want to create a dull, abrasive texture, getting rid of any smooth or glossy finish.

- Apply the Vulcanizing Fluid: Squeeze a thin, even layer of the rubber cement over the scuffed-up spot. Make sure the area you cover is a bit larger than the patch you're about to use.

- Let It Dry (Seriously): This is where most people go wrong. They get impatient. You need to let the fluid dry completely. It should go from shiny and wet to having a dull, matte look. If you touch it, it should feel tacky, not wet.

Applying the Patch or Plug

Once the vulcanizing fluid is ready, peel the backing off your patch and press it firmly over the hole. I mean, really press on it. Use your thumb and apply steady, hard pressure for at least a full minute. This ensures the chemical reaction creates a bond that's just as strong as the original tube.

If you have a tubeless tire, the process is a bit different. Your kit will come with two T-handle tools: a reamer and a plug installer. First, shove the reamer into the hole and work it around to clean out any debris and create a nice, uniform channel. Next, thread one of those sticky rubber plugs through the eye of the installer tool, push it into the hole until about half an inch is sticking out, and then yank the tool straight back out. The plug stays put, sealing the leak instantly.

A well-applied patch or plug isn't just a temporary fix—it's a permanent one. The key is taking your time with the prep work. A rushed job now will just have you doing this all over again in a week.

The technology behind these simple kits is always getting better. The tire repair patch market is projected to grow from USD 648.3 million in 2025 to nearly USD 950.4 million by 2035. This growth is fueled by better materials and stronger adhesives that make roadside repairs easier than ever. You can see the full market forecast on Future Market Insights for a deeper dive.

The core principles are the same whether you're working on a scooter or another set of wheels. In fact, you can check out our guide on how to handle e-bike tire repair for more tips that apply across the board.

Putting It All Back Together for a Safe Ride

Alright, you've wrestled the old tire off, and now it's time for the final boss: getting the new one on. This part can feel just as stubborn as the removal, but a few tricks of the trade make it a whole lot easier. Just remember, patience is the name of the game here.

You're basically just doing everything in reverse. Start by seating one side of the tire bead onto the rim. A little soapy water wiped along the inside of the tire and the rim's edge will be your best friend, helping things slide into place without a fight.

Getting the Tire and Tube Seated Just Right

With one side of the tire on, it’s time to slide the inner tube in (if you're using one). Pay close attention here—this is prime time for a "pinch flat," which is when you accidentally puncture your brand-new tube before you even ride on it. It’s incredibly frustrating.

Here's how to avoid that rookie mistake: Inflate the new inner tube just enough to give it some shape. You're aiming for a floppy sausage, not a rigid balloon. This little bit of air helps it sit properly inside the tire and keeps it from getting caught under the bead as you lever the second side on.

Now you can start working the other side of the tire bead over the rim. Take it slow, use your tire levers carefully, and work in small sections. Try to push the bead down into the center channel of the rim as you go; this will give you the slack you need to get that last, stubborn section over the edge.

Inflation and Final Safety Checks

Once the tire is fully on the rim, you can finally inflate it. Grab your pump and look for the recommended PSI (pounds per square inch) printed right on the tire's sidewall. Don't eyeball it! Under-inflating is a major cause of flats and can make your scooter handle poorly.

Now, you can bolt the wheel back onto the scooter. This is where that picture you took earlier is a lifesaver. Put every single washer and spacer back in the exact order they came off. Slide the wheel into place, reconnect your motor cables if you have them, and get those axle nuts good and tight.

Don't hop on just yet. Run through these final checks first:

- Spin the wheel. Does it move freely? Listen for any scraping sounds from the brake disc hitting the pads. If you hear rubbing, you'll likely need to readjust the brake caliper.

- Check the nuts again. Seriously. Give the axle nuts one last turn with your wrench to make sure they're secure. A loose wheel is a recipe for disaster.

- Clean up. Wipe down the tire and rim to get rid of any soapy water or grease.

A solid repair scooter tire job always ends with a quick, careful test ride. For more ways to keep every ride safe, check out our guide on essential electric scooter safety tips.

Now, go enjoy that smooth ride. You earned it.

Repair or Replace? Making the Call on Your Scooter Tire

So you've got a flat. Before you grab the patch kit, you need to figure out if a DIY fix is even the right move. Not every flat tire can be—or should be—repaired. Making the right call here is less about saving a few bucks and more about keeping yourself safe on the road.

A small, clean puncture, like the kind you get from a nail or a shard of glass right in the middle of the tread? That's the perfect candidate for a patch or a plug. It's a straightforward fix that will get you rolling again in no time. For most riders looking to repair scooter tire problems themselves, this is the best-case scenario.

Red Flags: When a Replacement Is Non-Negotiable

On the other hand, some damage is a deal-breaker. If you spot any of the following, don't even think about patching it. It's time for a new tire, period.

The absolute biggest no-go is any damage to the sidewall. The sidewall of a tire flexes constantly and isn't built to hold a patch. A repair there is just asking for a blowout, and it’ll probably happen at the worst possible time.

Here are a few other signs that scream "replace me":

- Big Gashes or Tears: If the hole is bigger than a quarter-inch (6mm), it's generally too large to plug safely.

- You Can See the Cords: See any fabric or metal threads poking through the rubber? That tire's structural integrity is shot.

- Worn-Down Tread: Check for the wear indicator bars on your tire. If the tread is worn down to that level, the tire is bald and won't give you the grip you need, especially when it’s wet.

- Multiple Punctures: A tire that looks like it's been through a warzone with multiple holes is too compromised to trust.

Your tires are the only thing connecting you to the ground. Gambling on a sketchy repair to save a few dollars just isn't worth risking your safety.

Giving Your Tire an Honest Assessment

I like to think of it like a pair of old running shoes. You can easily replace a broken shoelace (a small puncture), but you wouldn't bother trying to glue the sole back on when it's worn completely through. Same logic applies. A tire with thin, bald tread just can't provide the traction you need to stay upright, especially if you're on an all-terrain electric scooter that sees more than just smooth pavement.

It's a huge market. The entire two-wheeler tire industry was valued at around USD 14.2 billion in 2023, and the scooter tire segment alone was worth about $1.9 billion back in 2021. That tells you just how many people are out there relying on their tires every single day. If you're curious, you can discover more insights about the tire sealant market on industryresearch.biz. At the end of the day, knowing when to fold 'em and get a new tire is the most critical part of the job.

When it's time for an upgrade or a new ride, Punk Ride has a curated selection of high-performance electric scooters and bikes from top brands. Find your perfect match for effortless and eco-friendly city travel at https://www.punkride.com.

Share:

How to Choose an Ebike: A Clear Guide to Motors & Batteries

What Is the Electric Bike Insurance Cost in Australia and the US?